Expert Grease Pit Pumping System Repairs by Fluid Sealing: Top Emergency Signs

09 January 2025

Get expert grease pit pumping system repairs in Melbourne by Fluid Sealing. We provide reliable service to prevent downtime with top emergency repair solutions.

When your grease pit pumping system fails, timely and professional repairs are essential to avoid disruptions in operations. Fluid Sealing, based in Melbourne, specialises in grease pit pumping system repairs, offering efficient emergency services.

The Essence of a Grease Pit Pumping System

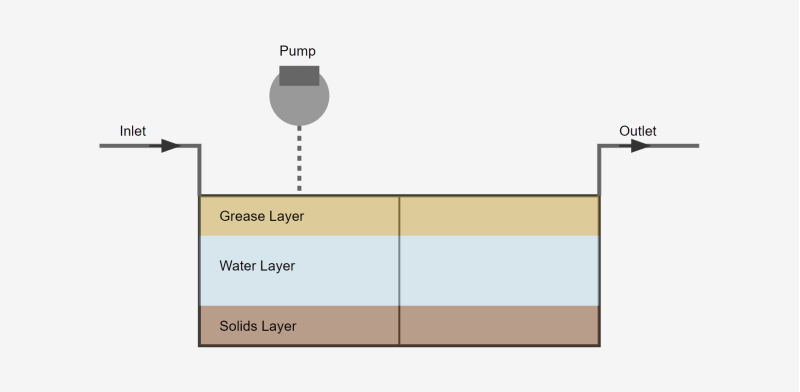

A grease pit pumping system is a specialised waste management system used to collect and dispose of grease, oil, and other waste materials from industrial environments, particularly in workshops, automotive service centres, and food processing plants. The system is designed to handle the removal of fats, oils, and grease (FOG) that accumulate during various operations, such as vehicle maintenance, food preparation, and machinery servicing.

However, like all mechanical systems, grease pit pumps require maintenance and occasional repairs to ensure optimal performance.

Invest in Grease Pit Pumping System Repairs

Recognising the early warning signs of a malfunctioning grease pit pumping system can prevent more costly repairs or system failure. Here are the top emergency signs to watch out for, ensuring you can address issues quickly with expert repairs.

• Unusual Noises from the Pump: If you begin hearing strange or unusual noises, such as grinding, rattling, or high-pitched whining, it’s a sign that something is wrong. These noises could signal a lack of lubrication, worn-out parts, or an issue with the pump impeller. If not addressed promptly, the issue can escalate into a total breakdown, leading to more expensive repairs or a replacement.

• Slow or Inefficient Pumping: If the pump is taking longer than usual to evacuate grease, oil, or other waste products from the pit, it’s a red flag. Sluggish pumping can indicate clogging in the system, damaged valves, or problems with the pump’s impeller or motor. A reduction in pumping efficiency also puts the system under strain, potentially causing long-term damage if not fixed.

• Unpleasant Odours or Leaks: Grease pit pumps should operate in a contained, sealed system. If you notice unpleasant odours or leaks around the pump or pit, this could signal a problem with the seals, pipes, or pump housing. Leaks allow waste materials to escape, which can lead to contamination, safety hazards, and a costly cleanup process.

• Pump Motor Overheating: Another common sign that your grease pit pumping system requires repair is an overheating motor. If the motor is running hot, it could be due to an overworked pump, a failure of the cooling system, or electrical faults. Overheating can lead to permanent damage to the motor and other components, causing the system to fail entirely.

• Excessive Vibration: Excessive or irregular vibration is another indication that something is amiss with your grease pit pumping system. Vibration can be caused by a variety of issues, such as misalignment of the pump, an imbalance in the impeller, or worn-out bearings. These issues can cause further damage to the pump and surrounding equipment if not addressed quickly.

Hire Fluid Sealing for Your Grease Pit Pumps

Grease pit pumping systems are essential for maintaining clean and safe working environments in various industries. If you encounter any of these signs, it’s essential to consult Fluid Sealing for repairs as soon as possible. Prompt attention to these issues will not only extend the lifespan of your system but also ensure its efficient operation, keeping your business running smoothly.

Optimized by: Netwizard SEO