Cooling Tower Pump Upgrade Solutions for Energy-Efficient Buildings

20 February 2025

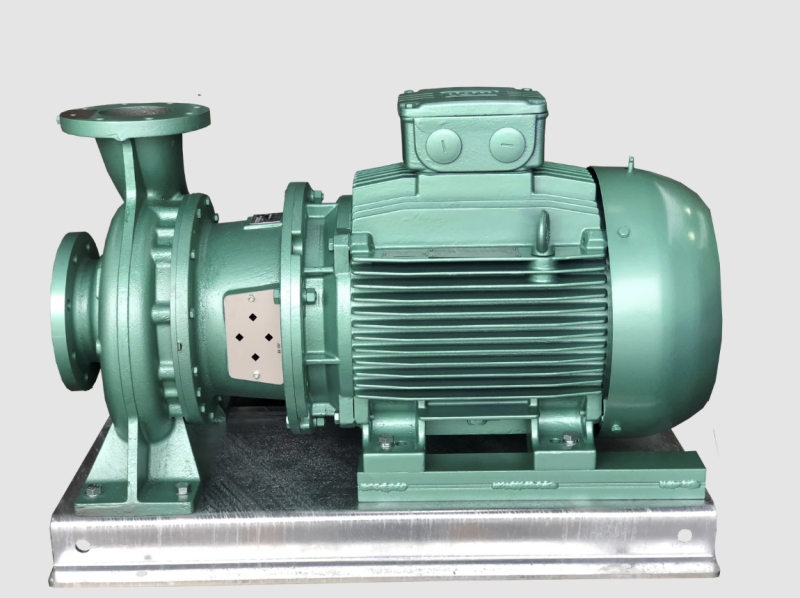

Fluid Sealing delivers cooling tower pump upgrade services that improve performance, reduce energy consumption, and support sustainable practices.

Cooling Tower Pump Upgrade: Maximising Energy Efficiency in Commercial Buildings

Upgrading cooling tower pumps can significantly enhance energy efficiency and reduce operational costs. Advanced pump technologies improve water flow and alleviate system strain, ensuring consistent cooling in commercial environments. These upgrades not only optimise energy use but also extend the lifespan of cooling systems, supporting sustainable practices.

For more insights on cooling tower pump upgrades and their benefits, consider exploring the U.S. Department of Energy’s guidelines on cooling tower management.

Incorporating modern cooling tower pumps lowers energy expenses while ensuring dependable and consistent performance. Selecting upgrades tailored to a building’s unique needs allows operators to minimise maintenance while maximising operational reliability. This strategy not only drives energy efficiency but also supports sustainability objectives, positioning businesses as leaders in environmentally responsible practices.

Smart Decisions for a Cooling Tower Pump Upgrade That Lasts

Upgrading cooling tower pumps goes beyond replacing outdated parts; it focuses on creating a system that is efficient and reliable. Businesses can maximise overall performance and minimise energy consumption by matching renovations to individual building requirements. Thoughtful planning ensures long-term cost savings and consistent operation.

Pump technologies at present offer smart solutions that improve efficiency and durability while simplifying maintenance. Modern upgrades can lower energy consumption, minimise wear, and enhance system monitoring for seamless performance. These advancements make it easier to maintain sustainable and dependable cooling systems.

Consider these six modern upgrades:

1. Variable Frequency Drives (VFDs): Dynamically regulate motor speeds to precisely match cooling requirements, significantly reducing energy consumption and operational costs.

2. Magnetic Coupling Pumps: Replace traditional seals with magnetic technology, minimising maintenance needs while ensuring long-term system reliability and performance.

3. High-Efficiency Impellers: Optimise water flow by reducing resistance, improving pump efficiency, and decreasing overall energy consumption.

4. Smart Monitoring Systems: Offer real-time data on pump operations, enabling predictive maintenance and ensuring peak efficiency with minimal downtime.

5. Corrosion-Resistant Components: Extend system lifespan by resisting wear and damage in harsh or chemically aggressive environments.

6. Energy-Efficient Motors: Maintain high performance while consuming less power, reducing operational expenses and supporting eco-friendly initiatives.

7. Enhanced Bearing Designs: Reduce friction to improve pump efficiency and minimise wear over time.

8. Noise Reduction Features: Provide quieter operation for a more comfortable work environment.

9. Thermal Performance Coatings: Boost heat transfer to maximise cooling efficiency.

Upgraded Filtration Systems: Prevent debris buildup to maintain smooth operations and minimise maintenance.

Fluid Sealing for All Mechanical Services & Pump Solutions – View Our Services

Enhancing equipment performance and reliability, Fluid Sealing is a trusted provider of pump and mechanical services in Melbourne. Our expertise in precision engineering and high-quality materials ensures tailored solutions for various operational needs. Implement advanced cooling tower pump upgrades to achieve precision in energy efficiency and system reliability.

Optimized by: Netwizard SEO