How Ceramic Resurfacing Extends Pump Life and Cuts Corrosion Costs

09 September 2025

Protect industrial pumps in Melbourne with Fluid Sealing’s ceramic resurfacing to reduce corrosion, cut downtime and extend reliable service life.

Why Pumps Fail in Harsh Environments

Protect industrial pumps in Melbourne with Fluid Sealing’s ceramic resurfacing to reduce corrosion, cut downtime and extend reliable service life.

Industrial pumps work under extreme pressure— literally. From saline water in desalination plants to chemical exposure in processing facilities, corrosion eats away at metal surfaces. The result? Unplanned breakdowns, higher maintenance costs, and costly downtime disrupt entire operations.

Ceramic Resurfacing: A Smarter Solution

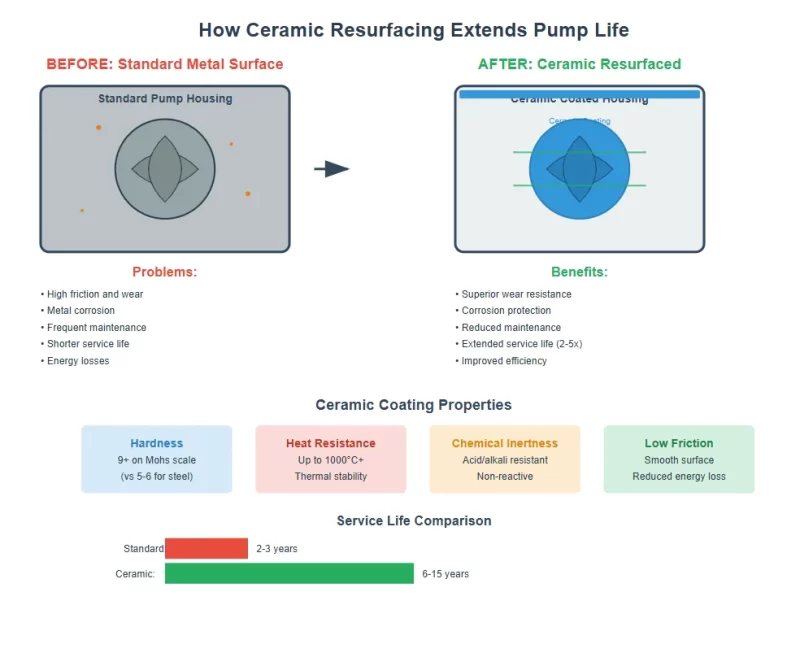

Ceramic resurfacing creates a strong, protective barrier inside pump housings and wetted parts, helping industrial pumps withstand harsh operating conditions. This advanced layer prevents damage caused by corrosive chemicals, abrasive particles, and saltwater, ensuring reliable performance over time.

Unlike standard coatings, ceramic resurfacing improves efficiency by creating a smooth flow path that reduces friction and energy loss. It also endures high temperatures and continuous wear, extending pump service life and reducing the need for frequent repairs.

Key Advantages for Industry

Industrial pumps face constant challenges from corrosion, abrasive materials, and harsh operating conditions. Ceramic resurfacing provides a reliable solution to enhance performance and durability.

Here are the key advantages of ceramic resurfacing for industrial operations:

• Longer Equipment Life – Significantly extend the operational lifespan of pumps by forming a resilient barrier that resists severe wear, erosion, and chemical damage.

• Efficiency Gains – Optimise hydraulic performance with smoother internal flow channels, reducing friction losses and improving energy efficiency.

• Reduced Maintenance – Minimise unplanned downtime with fewer repairs and replacements, lowering overall lifecycle and maintenance costs.

• Operational Reliability – Ensure continuous, trouble-free operation by reducing unexpected pump failures in critical industrial processes.

According to a study published by Materials Performance titled “The Science Behind It: Coating Technology for Pump Energy Savings”, advanced protective coatings applied to pump components significantly improve efficiency while reducing corrosion and wear. These findings support the growing use of ceramic resurfacing as a long-term solution for pump reliability and cost savings.

Where Ceramic Resurfacing Delivers the Most Value

Industries face different challenges that can lead to premature wear and corrosion in pump systems. Advanced ceramic coating solutions provide reliable protection to improve performance and extend the operational lifespan of equipment.

Here are the sectors where these protective surface treatments deliver the most value:

• Mining – Defends pumps against severe slurry abrasion, chemical leaching, and particulate erosion common in mineral processing and extraction.

• Desalination – Protects high-pressure systems from saltwater corrosion, scaling, and pitting to maintain long-term reliability and efficiency.

• Chemical Processing – Creates a tough, impermeable barrier to withstand constant exposure to aggressive acids, alkalis, and industrial solvents.

• Municipal Water – Enhances the durability and performance of pumps in essential public facilities where continuous operation is critical.

Why Partner with Fluid Sealing?

At Fluid Sealing, we don’t just sell pumps—we protect them. Our ceramic resurfacing services are backed by industry expertise and supported by a full range of quality brands, including Grundfos, Wilo, KSB Ajax, and more.

Whether you operate in mining, water treatment, or chemical processing, our tailored surface protection solutions help your equipment last longer and perform better.

Contact us to discuss how ceramic resurfacing can solve your pump corrosion challenges.

Related Blog Articles:

Ceramic Resurfacing vs. Conventional Coatings: Differences in Pump Surface Protection

Ceramic Resurfacing: The Ultimate Solution for Pump Corrosion in Harsh Environments

Optimized by: Netwizard SEO