Pump Gasket Selection: Material Properties and Compatibility Considerations

25 July 2024

Discover the key considerations when selecting a pump gasket. Learn the common gasket material and choose the right one for your application with Fluid Sealing.

Selecting the right pump gasket is a critical decision that can significantly impact the performance, efficiency, and longevity of your pumping system. As Melbourne’s leading pump specialists, Fluid Sealing understands the importance of choosing the appropriate gasket material for your specific application.

Understanding Pump Gaskets

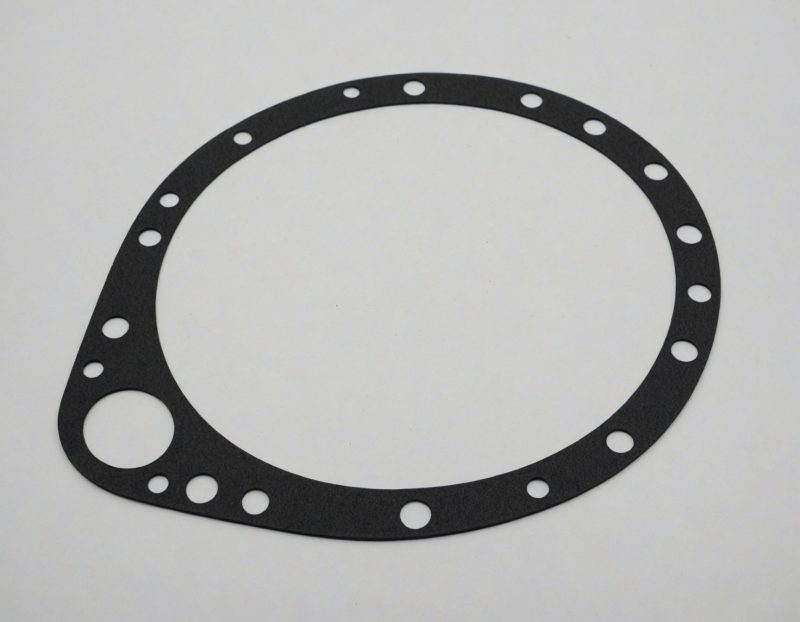

Pump gaskets play a vital role in creating a seal between two surfaces in a pumping system, preventing leaks and maintaining pressure. The right gasket ensures optimal pump performance, reduces maintenance costs, and enhances overall system reliability. However, with a wide range of materials available, choosing the perfect pump gasket can be a challenging task.

Material Properties

When selecting a pump gasket, it’s essential to consider the following material properties:

• Chemical resistance

• Temperature tolerance

• Compression set

• Tensile strength

• Flexibility

• Durability

• Permeability

Each of these properties contributes to the gasket’s ability to maintain an effective seal under various operating conditions. For instance, a gasket with high chemical resistance is crucial in applications involving corrosive fluids, while temperature tolerance is vital for pumps operating in extreme heat or cold.

Compatibility Considerations

Compatibility between the gasket material and the pumped fluid is paramount. A gasket that’s incompatible with the fluid can degrade quickly, leading to leaks, contamination, and potential system failure. When assessing compatibility, consider the chemical composition of the fluid, operating temperature range, pressure requirements, mechanical stress on the gasket, and potential for abrasion or erosion.

Selecting the Right Pump Gasket

To choose the most appropriate pump gasket for your application, follow these steps:

• Identify the operating conditions: Determine the temperature range, pressure, and chemical composition of the fluid being pumped.

• Assess the mechanical requirements: Consider factors such as flange surface condition, bolt load, and potential for vibration or movement.

• Evaluate material properties: Compare the properties of different gasket materials against your specific requirements.

• Consider longevity and maintenance: Factor in the expected lifespan of the gasket and ease of replacement.

• Consult with experts: Reach out to Fluid Sealing’s team of specialists for personalised advice on pump gasket selection.

Custom Solutions

In some cases, off-the-shelf gaskets may not meet the unique requirements of your pumping system. At Fluid Sealing, we offer custom gasket solutions, including die-formed gaskets and spiral-wound gaskets, tailored to your specific needs. Our expertise in gasket technology allows us to create bespoke solutions that ensure optimal performance and longevity.

Fluid Sealing: Your Partner in Pump Expertise

Selecting the right pump gasket is a crucial decision that requires careful consideration of material properties and compatibility factors. By understanding these key elements and leveraging the expertise of Fluid Sealing’s specialists, you can ensure that your pumping system operates at peak efficiency with minimal downtime and maintenance costs.

Remember, the right pump gasket is an investment in the reliability and performance of your entire pumping system. Don’t hesitate to reach out to Fluid Sealing for expert advice on selecting the perfect gasket for your application. Our commitment to quality and customer satisfaction ensures that you’ll receive the best possible solution for your pump sealing needs.

Optimized by: Netwizard SEO