Shaft Laser Alignment: Solving Common Misalignments in Industrial Pump Systems

26 November 2024

Ensure peak performance in industrial pump systems with Fluid Sealing’s precise shaft laser alignment, reducing wear, downtime, and maintenance costs.

Shaft laser alignment is a precise method used to align the shafts of rotating machinery. It utilises laser technology to measure misalignments with high accuracy, ensuring that the shafts are parallel and properly aligned along their axes.

This process helps to identify and correct common misalignments, such as angular and parallel misalignments, which can cause excessive wear, vibrations, and energy losses in pumps and machinery. Implementing shaft laser alignment enhances performance and extends the lifespan of equipment, reducing maintenance costs and downtime.

How Shaft Laser Alignment is Done

Shaft laser alignment is performed through a series of systematic steps to ensure precise alignment of rotating machinery. Here’s how it typically works:

1. Setup: The laser alignment tool is positioned on one shaft, with a laser transmitter mounted securely. A reflector is then placed on the opposite shaft.

2. Measurement: The laser emits a beam that reflects off the reflector back to the receiver on the transmitter. It measures the alignment between the two shafts.

3. Data Analysis: The alignment tool subsequently collects data on angular and parallel misalignment, presenting it in a readable format.

4. Adjustment: Based on the readings, adjustments are made to align the shafts correctly. It may involve moving one or both shafts horizontally or vertically.

5. Verification: After adjustments, measurements are taken again to confirm that the shafts are properly aligned within acceptable tolerances.

6. Final Checks: The entire system is checked for operational integrity, ensuring optimal performance.

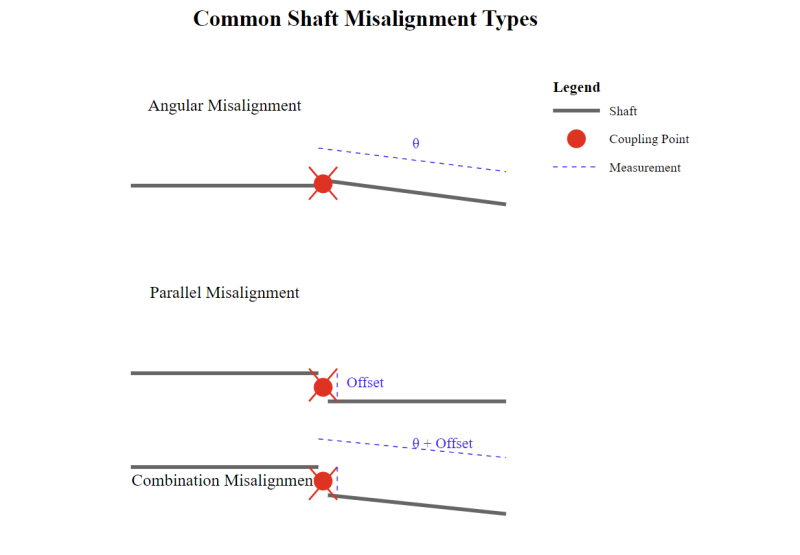

Common Misalignments in Industrial Pump Systems

Numerous misalignments in machinery and industrial pumps necessitate the need for shaft laser alignment. Some of them are as follows.

1. Angular Misalignment: Angular misalignment occurs when shafts are not aligned along the same axis, leading to increased wear on bearings and components due to excessive vibration and stress.

2. Parallel Misalignment: When two shafts are parallel but offset, it creates uneven loading, increasing friction and heat. It can lead to premature failure of seals and bearings.

3. Radial Misalignment: Radial misalignment results from the rotation of shafts not being perfectly concentric, causing uneven wear and reduced efficiency.

4. Thermal Expansion Misalignment: Fluctuations in temperature can cause components to expand or contract, leading to misalignments that may not be evident until performance issues arise.

Through shaft laser alignment, experts can accurately diagnose and correct these misalignments, ensuring optimal performance, reducing maintenance costs, and prolonging machinery life.

Many machines can undergo shaft laser alignment regularly to ensure they operate efficiently and without unnecessary wear. Pumps can undergo this process to prevent potential leaks and bearing damage. Other machines that can benefit from this process include motors, gearboxes, compressors, and generators.

Applications in Industrial Pumps

Shaft laser alignment is a valuable practice for maintaining the reliability of various pump systems, including:

• Centrifugal Pumps

• Positive Displacement Pumps

• Vertical Pumps

• Multistage Pumps

By employing this advanced alignment method, pump systems can achieve optimal performance, reduce the risk of leaks, and ensure smoother operation across various industrial applications.

Regular shaft laser alignment by Fluid Sealing Mechanical Services and Pump Specialists should be a cornerstone of any maintenance program for industrial pumps to maximise their operational efficiency and reliability.

Optimized by: Netwizard SEO